Freshly Cut Wood Stacked for Lumber Air Drying Close Up Free Stock Photo picjumbo

Wood Drying Kiln Computerised Wood Drying Kiln Supplier Machinery Ltd, Kampala Uganda

We offer fast and reliable Vacuum Kiln Drying Services for most wood slabs and dimensional lumber. Hardwoods or recently milled slabs, we recommend air drying to 20-30% moisture content prior to being loaded into the kiln. In some cases, softwood species don't require any air drying and can go directly from the mill to the kiln.

Kiln Dried Firewood., Kiln Dried Cooking Wood And Bundles Smoak Firewood Senoia, Ga Kiln

Start kiln drying lumber with the Wood-Mizer KD450 dehumidification wood kiln drying system for up to 15,000 board feet of lumber. Featuring 100% corrosion resistant aluminum cabinets and specially coated dehumidification coils to ensure quality lumber drying performance and an extra-long life.

Properly Kiln Drying Antique Wood

Faster Drying Times: Vacuum kiln technology removes moisture from wood significantly faster than conventional methods, reducing wait time and increasing productivity. Superior Quality Wood: Our controlled drying process minimizes Wood warping, cracking, and uneven drying, ensuring exceptional final product quality. Energy Efficiency: Vacuum kilns consume less energy than traditional DH Kilns.

Understanding the Wood Kiln Drying Process & Why It Is Important?

It all comes down to time and quality. Waiting for wood to dry outdoors is a long process! In open air, wood will need an entire year per inch to dry. In the Kiln (or VacDry), Cedar can be dried in just a few days, Pecan will take a couple of weeks and a 3" Walnut slab will require 4 weeks. It is important that wood be dry prior to using it.

Freshly Cut Wood Stacked for Lumber Air Drying Close Up Free Stock Photo picjumbo

Air drying can take anywhere from one week to six months. $2 / bd. ft., extra charges for pick-up and delivery apply; Kiln Dried Wood Once wood has been air dried to approx. 30% moisture content, we lock it in the kiln to finish the drying process. Wood is sticker stacked in the Kiln to minimize warping and cupping.

Wood Dry Kilns Wellons Fei

Ruben Custom Sawmill & Woodworks. Welcome to our world of custom wood! We specialize in Live Edge Slabs, Milling, Vacuum Kiln Drying, and Custom Finished projects. We can also assist with your personal project materials and have an incredible inventory of wood products available for every project!

Fundamental Aspects of Kiln Drying Lumber Oklahoma State University

We also offer kiln drying to other wood enthusiasts, woodworkers, and hobbyists looking to add value to their wood and make it more workable and home-ready. Pricing. $0.20 per board foot/day. Pricing. $0.20 per board foot/day. $300 minimum charge. Kiln Capabilities. Up to 2000 bd/ft. 13' long.

Everything You Need to Know about KilnDried Wood in a Nutshell

Step 4: Build the Kiln. After a few months, bring the wood indoors and finish the drying. To build the kiln lay poly (clear plastic roll) on the ground and then build a frame with 2x4 studs on top of it for the lumber to rest on. Leave enough space to have a standard household dehumidifier at one end, and a small fan at the other.

How Much Does It Cost To Kiln Dry Wood? CostNiche

We are Arbor Custom Kilns. We offer kiln drying and sterilization services for residential and commercial clients looking to dry their dimensional lumber, slabs, and cookies by utilizing an iDry Plus vacuum kiln and monitoring moisture content with a Lignomat Moisture Meter. We can dry wood up to 16 feet in length and 5 feet in width.

All About Kiln Dried Wood Blog Old World Timber

At Byler's, we are here to help you find exactly the right piece of wood for your indoor application- whether for home improvement or artistic purposes. Wood is our passion and our customers know that. Our kiln dried, low-moisture wood is ideal for many of your woodworking projects-whether for a cabinet to display valued antiques.

The top 21 Ideas About Diy Kiln Drying Wood Home, Family, Style and Art Ideas

Kiln Drying. Our onsite dehumidification kiln enables us to offer kiln dried lumber to those who have indoor projects like furniture, cabinets, wood flooring, trim and baseboards. The kiln is also made available to customers that have their own lumber and need it dried. It has a maximum capacity of 3,000 board feet.

My Wood Drying Kiln woodworking Pinterest

Register For NEKDA 2024 At Lashway Lumber! Find Sawmill and Wood Drying Services, Furniture Makers, and More! Search to see who has an iDRY Kiln, Live Edge Slabs, or a Portable Sawmill Near you! Popular Categories Find Sawmill and Wood Drying Services, Furniture Makers, and More!

Dry Kilns Chisholm Forest Corp Chisholm Lumber YouTube

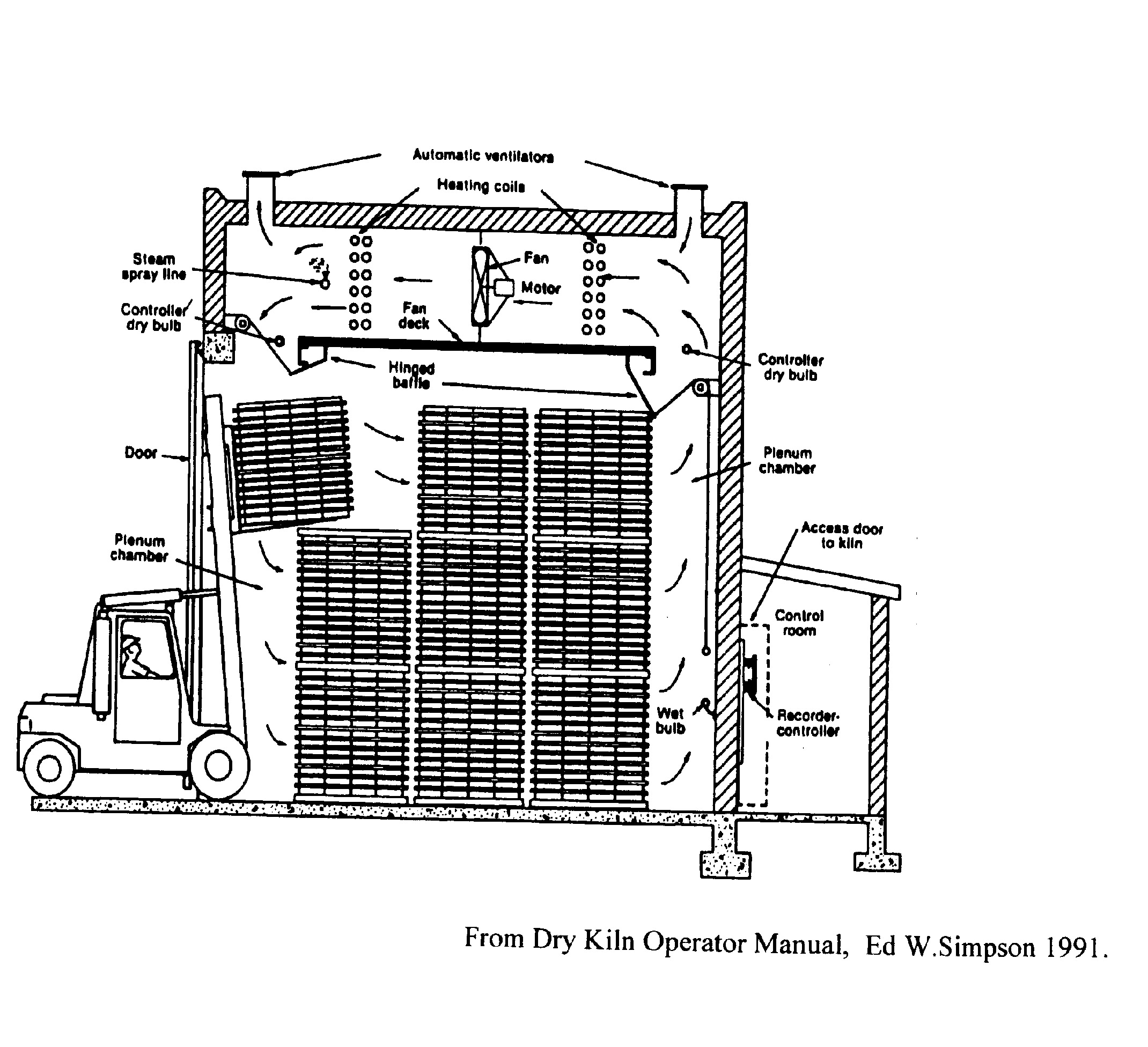

A better-circulated air will help the lumber to dry faster providing a more uniform drying. The fan will also help to cool the lumber so that it doesn't warp or crack. To install the fan, cut a hole in the top of the kiln. The hole should be big enough to fit the fan. Attach the fan to the hole with screws or bolts.

Kiln Drying 16D

KD550 Dehumidification Lumber Kiln. Starting at $49,495. Commercial dehumidification kiln for precise controlled lumber drying up to 35,000 board feet. SHOP NOW. Kiln dry lumber with a Wood-Mizer dehumidification kiln or solar kiln with lumber drying capacities ranging from 300 to 35,000 board feet.

JGUnitemp

Air-drying timber stack. Wood drying (also seasoning lumber or wood seasoning) reduces the moisture content of wood before its use. When the drying is done in a kiln, the product is known as kiln-dried timber or lumber, whereas air drying is the more traditional method.. There are two main reasons for drying wood: Woodworking When wood is used as a construction material, whether as a.

Best 21 Diy Kiln Drying Wood Home, Family, Style and Art Ideas

Custom Wood Kiln Drying. LaRue Woodworking offers custom wood kiln drying through dehumidification kiln technology to our customers. We are one of the few companies willing to dry small batches of hardwood in upstate NY. Our current kiln can hold up to 4000 bd-ft. Properly kiln-drying lumber involves maintaining strict control of temperature.